Tensile testing is one of the most widely used mechanical tests and is a destructive test. A tensile test helps to determine weld characteristics such as tensile strength, ductility and yield points.

Tensile Test Procedure

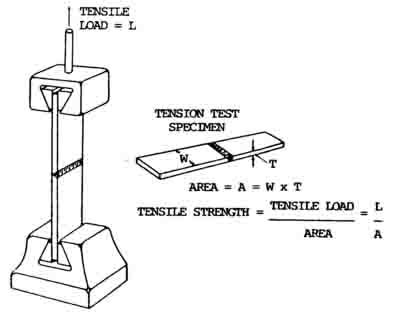

Tensile test is carried out by gripping the ends of a weld specimen in a tensile testing machine and applying an increasing pull on the specimen until it fractures.

During the test, the tensile load as well as the elongation of a previously marked gauge length in the specimen is measured with the help of load dial of the machine and extensometer respectively. These readings help plotting the stress strain curve.

After fracture, the two pieces of the broken specimen are placed as if fixed together and the distance between two gauge marks and the area at the place of fracture are noted.

Tensile strength

Tensile strength is the maximum tensile strength of the metal. Tensile strength is calculated by dividing the maximum tensile load by the cross-sectional area of the specimen. Tensile strength is measured as stress in pounds per square inch.

Ductility of a weld

Two standard measurements of ductility are the percent elongation and the percent reduction of area.

Percent elongation = [(Lf – L0)/L0] x 100

Where L0 is defined as the initial gage length and Lf is the length of the gage section at fracture.

Percent reduction of area = [(A0 – Af )/A0] X 100

Where A0 is the initial cross-sectional area and Af is the the cross-sectional area at fracture.

Yield strength

Yield strength or yield point is the initial maximum stress at which yielding or deformation is observed. More brittle materials do not yield before fracture but may have a high tensile strength.

Types of Tensile Tests

The two most commonly used types of tensile testing are transverse tensile testing and all weld metal tensile testing.

Transverse Tensile Test

In a transverse tensile a tension test specimen is cut at right angle to the weld direction and is used to determine the transverse tensile strength of the combined base metal and weld metal.

All Weld Metal Tensile Test

In an all weld metal tensile test, the specimen is prepared from all weld metal. This type of specimen is prepared by machining a groove in a plate of steel and then completely filling the groove with deposited weld metal. The surrounding steel is then machined away leaving a specimen of weld metal. The purpose of such a test is to test:

- Electrodes for their suitability for the job concerned,

- The quality of deposited metal in welded joint.